The COVID-19 epidemic is complicated and businesses in the aluminum industry are facing many difficulties

Vietnam’s Aluminum Industry Faces Challenges Due to COVID-19

With the shadow of COVID-19 looming over the industry, aluminum sector revenue was estimated to decline by 30% in Q1 2020, with a potential 40% workforce reduction in Q2 2020. In response, the Vietnam Association of Extruded Aluminum Profile Manufacturers for Construction and Industry (Vietnam Aluminum Profile Association – VAA) submitted Official Letter No. 11/CV-VAA to the Prime Minister, requesting government intervention to support the industry.

Specific Recommendations

VAA's proposals focus on six key areas:

-

Reduce VAT to 5%, corporate income tax to 10%, and export tax on aluminum profiles.

-

Lower interest rates and defer payments on short-term and medium-term loans for businesses.

-

Exempt or reduce road toll fees to cut logistics costs for companies.

-

Reduce or suspend social insurance contributions for at least six months and allow struggling businesses to delay social insurance payments.

-

Accelerate customs clearance for imports and exports.

-

Facilitate connections with suppliers of production materials outside China.

Mounting Challenges

1. Raw Material Supply Disruptions

Currently, 30% of raw and auxiliary materials used in Vietnam’s aluminum manufacturing sector are imported from China. Since February, border closures and strict disease control measures have severely impacted supply chains. If the situation worsens, many businesses could run out of raw materials by the end of April, forcing production to halt.

2. Declining Demand from the Construction and Export Markets

Since the Lunar New Year, the real estate market has been frozen, first due to the holiday break and later due to the escalating pandemic. This has led to a sharp decline in demand for construction aluminum, causing production and construction projects to stagnate. Furthermore, since early March, the rapid global spread of COVID-19 has restricted aluminum exports to the Americas and Europe.

3. Logistics and Supply Chain Disruptions

Supply chain delays and disruptions have worsened due to pandemic-related transport restrictions. Additionally, import customs clearance now takes significantly longer due to disinfection procedures and disease control measures, leading to delays in transportation and circulation of goods.

Proactive Responses

Despite these challenges, while awaiting government support, aluminum manufacturers have adopted self-adaptive measures to turn adversity into opportunity and sustain production.

Moreover, Vietnam’s closure of border crossings with China has helped curb illegal imports of aluminum, allowing domestic manufacturers to reclaim market share and enhance industry credibility.

Aluminum Industry Heavily Affected by COVID-19

These difficulties also present an opportunity for businesses to reassess and stabilize their development strategies, optimize operations, and regain momentum once the pandemic subsides. Additionally, this period fosters closer cooperation between aluminum manufacturers and related supporting industries, including chemical suppliers, mold makers, coatings, and packaging companies, helping the industry strengthen collaboration to overcome the current crisis.

Despite the aluminum industry’s proactive efforts, many companies have yet to access government support measures related to credit, taxation, or social insurance. To ensure survival and post-pandemic recovery, urgent government intervention is needed in three key areas:

-

Defer and reduce social insurance contributions

-

Lower and defer tax obligations

-

Provide access to bank credit relief

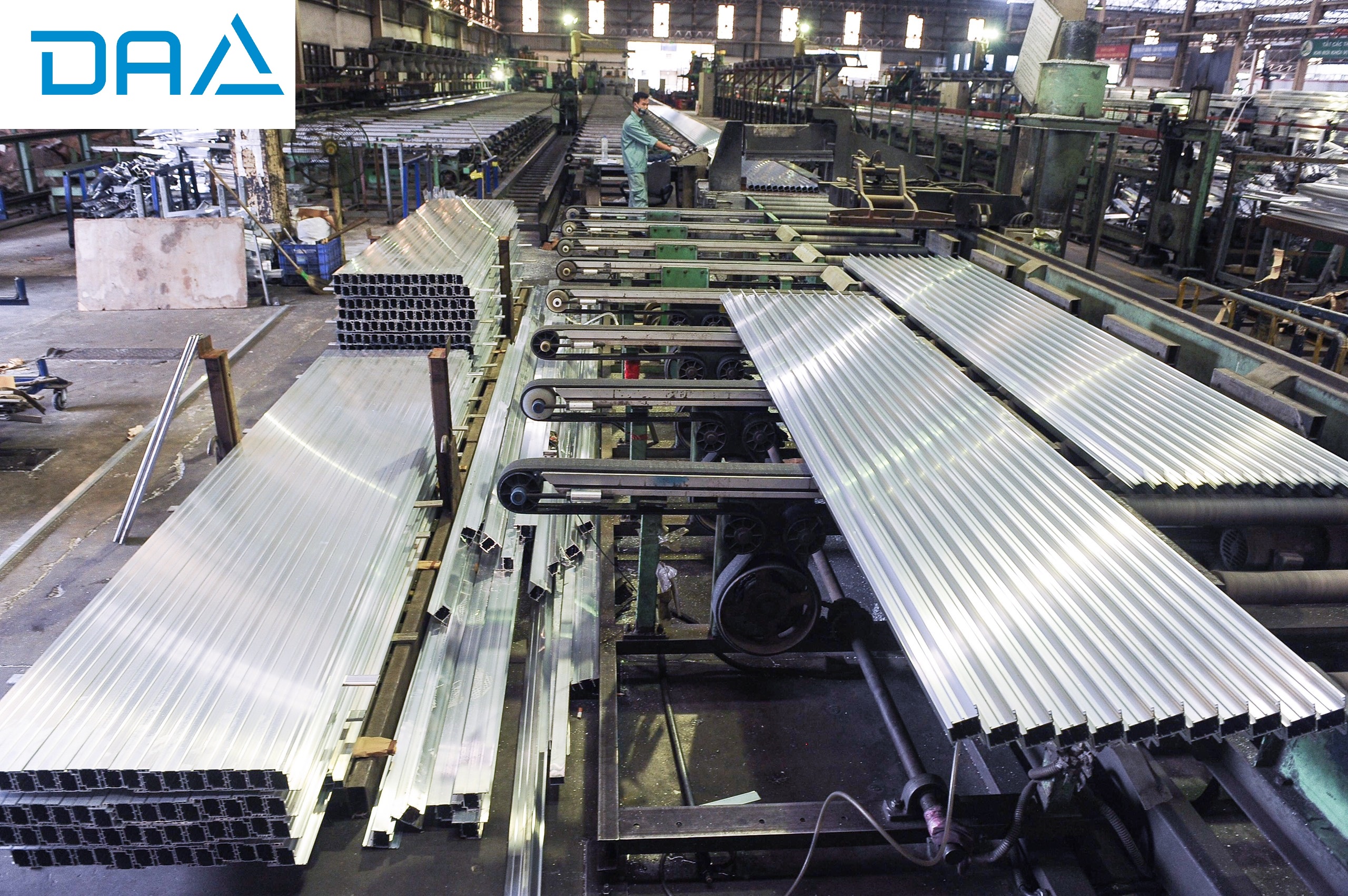

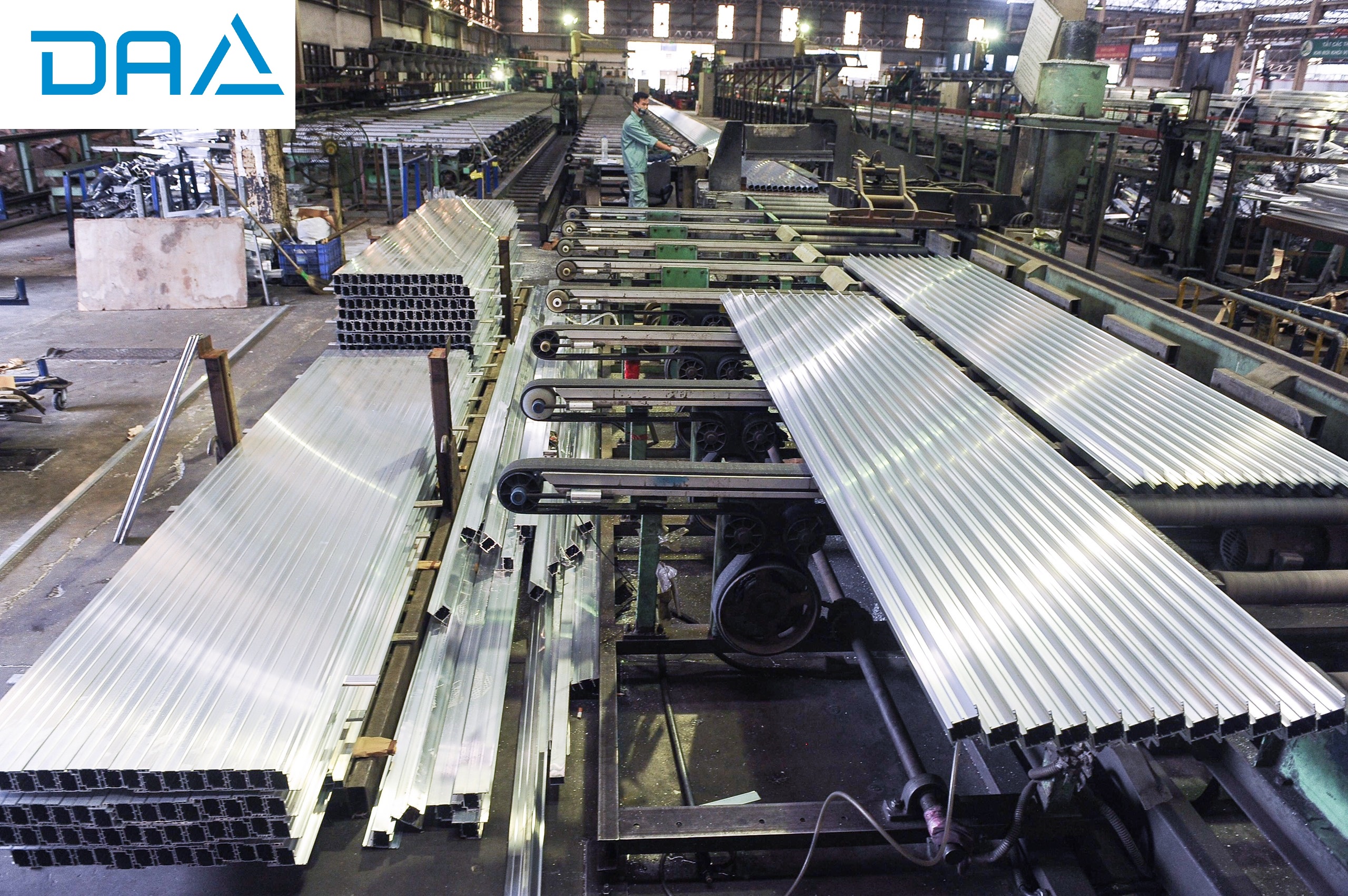

Dong Anh Aluminum Factory’s Response

As one of Vietnam’s leading aluminum suppliers, Dong Anh Aluminum Factory (a subsidiary of Dong Anh Licogi Mechanical Joint Stock Company) has proactively implemented preventive measures while maintaining production since the early days of the outbreak. These measures include:

✔ Shift rescheduling and rotational work shifts for employees

✔ Providing face masks and hand sanitizers for all staff

✔ Maintaining job security despite revenue declines

Although employee incomes have fluctuated due to lower sales volumes, CKDA and DAA remain committed to avoiding workforce reductions, ensuring stable employment and financial support for workers during this difficult time.

Source: enternews.vn

Email: info@ckda.vn

Email: info@ckda.vn 1900 988 932

1900 988 932